Introduction

Warehouses are the backbone of logistics, distribution, and industrial operations. But a warehouse is only as safe and productive as the lighting above it. Poor visibility leads to mistakes, accidents, and inefficiencies. With high ceilings and expansive floor space, the challenge is clear: how do you create consistent, ergonomic illumination?

This guide explores the essentials of warehouse lighting in South Africa, comparing high-bay LED lights with panel solutions to help operators make informed decisions.

Key Points:

- Warehouses demand specialised lighting for safety, accuracy, and compliance.

- High-bay LED lights are designed for high ceilings, offering powerful lumen output.

- LED panel fixtures suit lower-ceiling areas, offices, or hybrid warehouse spaces.

- Proper lighting design reduces accidents, increases productivity, and cuts costs.

- Local suppliers like View Lighting provide SANAS-certified, B-BBEE Level 2 fixtures tailored for warehouse environments.

The Importance of Proper Warehouse Lighting

Why Visibility Matters in Warehouses

Warehouses operate at scale, with forklifts, stock pickers, and fast-moving staff. Shadows, glare, or dim areas create safety risks. Consistent lighting ensures accuracy in inventory management and safer workflows.

Safety and Compliance

South African health and safety standards emphasise correct lux levels to minimise accidents.

Productivity and Accuracy

Clear lighting reduces picking errors and speeds up fulfilment.

Energy Efficiency Pressure

Warehouses run lights for long hours; efficiency directly impacts operating costs.

High-Bay LED Lights: The Warehouse Workhorse

What Are High-Bay LED Lights?

High-bay lights are engineered for ceilings typically 6–12 metres high, delivering concentrated brightness with wide coverage.

Advantages of High-Bay LEDs

- Powerful lumen output for expansive spaces.

- Long lifespan, reducing maintenance in hard-to-reach areas.

- Energy-efficient compared to legacy sodium or metal halide lamps.

Best Use Cases

- Storage zones with tall racking systems.

- Assembly lines in large industrial halls.

- Logistics hubs require uniform visibility.

Design Considerations

Optics and beam angles can be tailored to specific tasks, wide angles for open floors, narrow beams for racking aisles.

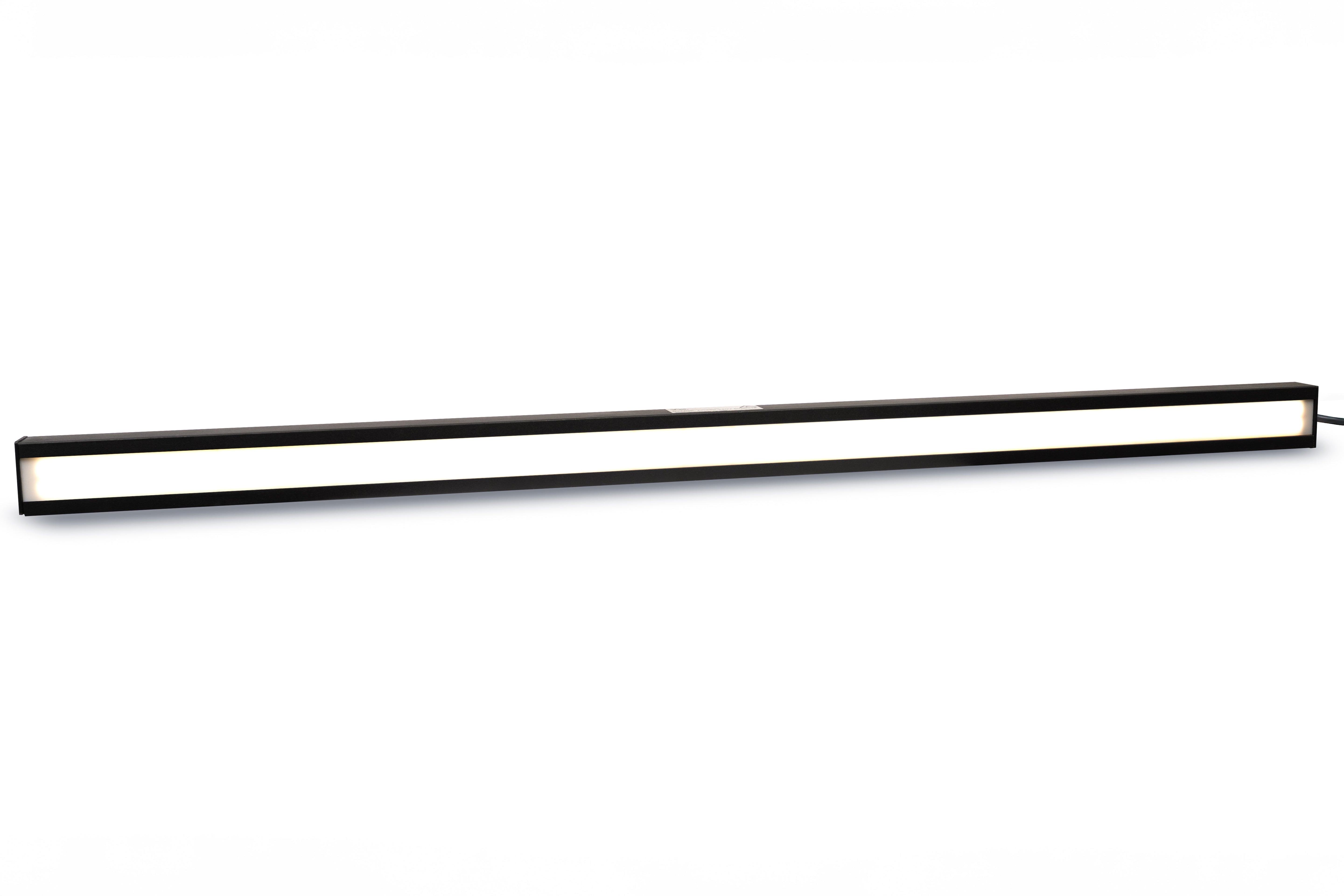

LED Panel Fixtures: A Flexible Alternative

When to Use LED Panels in Warehouses

While warehouse lighting fixtures are often associated with high-bays, LED panels still play a role in warehouse environments.

Benefits of LED Panels

- Slim design fits offices, control rooms, and lower-ceiling storage areas.

- Consistent, glare-free illumination ideal for desk-based or admin zones.

- Cost-effective for mixed-use warehouse spaces.

Limitations

Not suitable for ceilings above 4–5 metres due to limited light throw.

Integration Opportunities

Can be combined with high-bay LEDs for hybrid setups in warehouses that blend office and industrial tasks.

Designing the Right Warehouse Lighting System

Balancing Efficiency, Safety, and ROI

Warehouse lighting design isn’t about choosing one fixture type - it’s about creating a balanced system.

Layered Solutions

High-bays for main operational zones, LED panels for offices or mezzanines.

Ergonomic Considerations

Lighting colour temperature (CCT) and lux levels must match tasks — cooler light for focus, warmer light for relaxation spaces.

Smart Controls

Integrating sensors and automation reduces wasted energy in unused zones.

Conclusion

Optimising warehouse lighting in South Africa means more than just hanging fixtures, it’s about safety, productivity, and efficiency. High-bay LED lights dominate in high-ceiling spaces, while LED panels provide valuable support in offices or lower-ceiling sections. Together, they create a lighting ecosystem that supports both workers and the bottom line.

With SANAS-certified, locally manufactured fixtures, View Lighting helps logistics and warehouse operators build safer, more efficient environments that shine light where it matters most.

Visit View Lighting | Lighting Manufacturer

Address:

Unit 9, The Refinery Business Park,

George Allen St, Rietfontein 63-Ir,

Bedfordview, Germiston, 1401

Phone: 011 455 4900

Google Business Profile: Find us on Google

Facebook: View Lighting

LinkedIn: View Lighting

FAQs

1. Why are high-bay LED lights ideal for warehouses?

They provide strong, uniform illumination for high-ceiling spaces, improving safety and efficiency.

2. Can LED panels be used in warehouses?

Yes, but mainly in lower-ceiling areas like offices, control rooms, or admin spaces within the warehouse.

3. How does proper warehouse lighting reduce accidents?

By eliminating dark zones and glare, it ensures operators can move safely and accurately.

4. What’s the ROI of switching to LED warehouse lighting?

LEDs cut energy costs by up to 60% and reduce maintenance expenses due to longer lifespans.

5. Why choose View Lighting for warehouse lighting solutions?

View Lighting offers locally manufactured, SANAS-certified, B-BBEE Level 2 fixtures tailored for South African warehouses.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.